- Sales Tel: +86-571-82565091

- After-sales: +86-18057103828

- E-mail: m.koeddl@technic.de

- Description

- Case

Year-round professional services in the petrochemical industry has made us a leading integrated engineering services team, we deeply felt the service has long been customer demand for products, and all equipment suppliers provide service differentiation in a project and maintenance costs outside the warranty period is the perennial customer's challenges. To reduce customers ' maintenance costs and efficiency in late 2011, the company set up a professional engineering services team, we will adhere to the customers as the Center, with strong technical strength and advanced processing and testing equipment in order to ensure, to provide customers with a full range of equipment maintenance work.

The company has ten service teams, each team is equipped with a dedicated project manager, quality engineers, electrical engineers, mechanical engineers, technicians and other professionals.

2. Service project (P5)

●Oil line, a large oil depot, oil refinery, port and petrochemical enterprises of all critical equipment repair and maintenance:

Assembly and disassembly of equipment as a whole, wearing parts replacement

Spare parts of processing, repairs

Depth within the device cleaning and maintenance

Calibration of equipment commissioning Guide, parts

Performance testing of equipment

Provision of alternative devices during overhaul (overhaul facility for the company's products only)

●Oil line, a large oil depot, oil refinery, port and petrochemical enterprises of all critical equipment maintenance all year round:

Monthly preventative inspection, and maintenance

Temporary equipment maintenance (includes disassembly, wearing parts replacement, cleaning and maintenance of equipment)

Planned equipment maintenance work

Performance testing of equipment

On-site technical training of operators

●Oil line, a large oil depot, oil refinery, port and petrochemical analysis and energy efficiency consulting solutions:

Optimization of energy consumption,

Systems management

Automation framework integration

Smart device support

●Oil line, a large oil depot, oil refinery, port and petrochemical Enterprise remote monitoring:

Provide feasibility program

Install surveillance equipment and the establishment of monitoring systems

3. project case studies

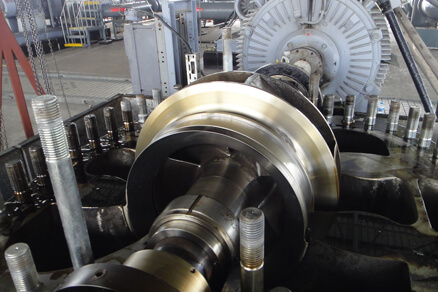

In recent years the company has been involved in pipeline overhaul and maintenance work, such as Shandong and Anhui Provinces a Flower oil pump rotor repair and manufacturing work, Shi-Tai line rule 12stage pump maintenance and renovation work, Shanghai-Nanjing line Ruhr oil pump repair and maintenance work.

Oil transfer station

Pump station

Pump body opening

Pump body cleaning

Rotor balance testing

Assemlbing

Correction

Testing in factory

Testing in factory

Testing in factory