- Sales Tel: +86-571-82565091

- After-sales: +86-18057103828

- E-mail: m.koeddl@technic.de

- Description

- Parameters

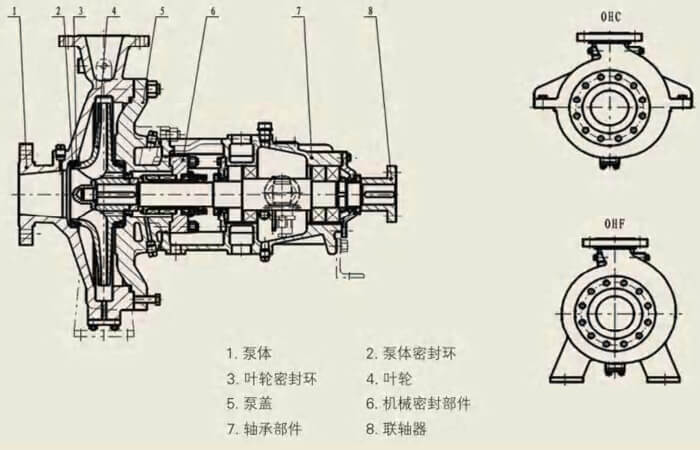

- Structure Performance

- Configuration

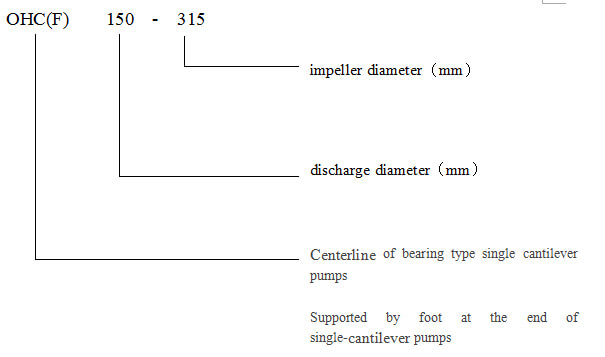

2. horizontal and Cantilever, Radially-Split, Centre line- or Foot-Support, Meeting OH1、OH2 structures.

3. Design of from behind pull out type, convenient maintenance and reliable operation

4. Standard seal meeting requirements of API 682

5. Obtained 2 national patents

6. Applicable for transport of various petroleum chemical medium

7. Temperature range: -35~425℃

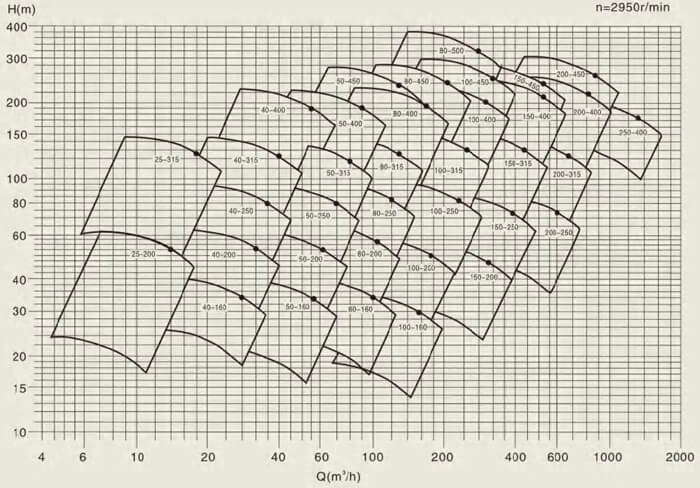

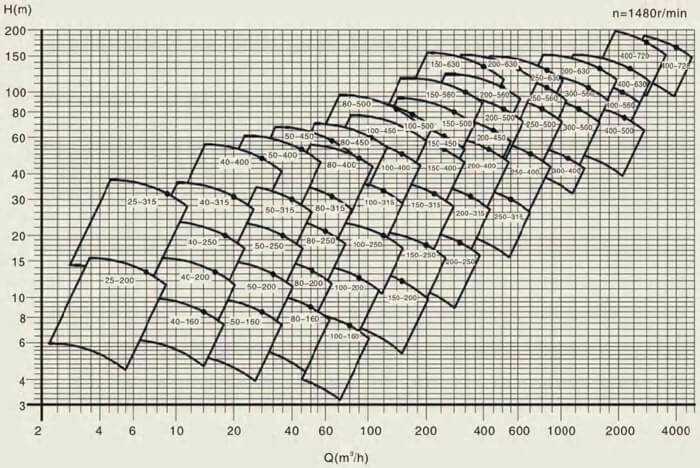

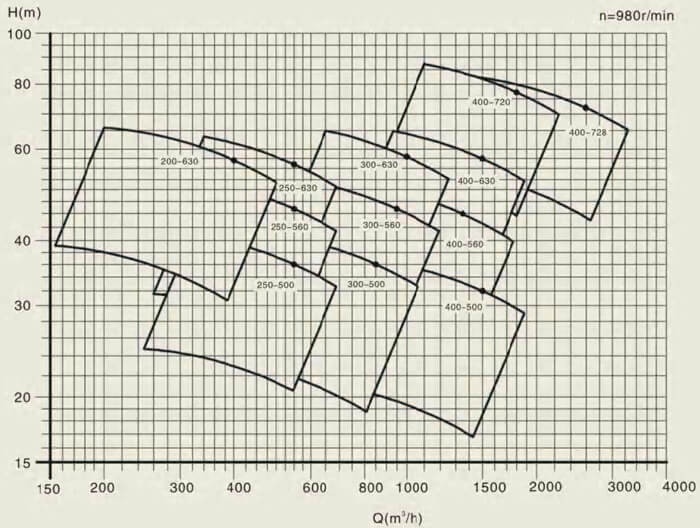

8. Flow: 5~4000m3/h

9. Head: 5~325m

| Model | speed 1480r/min | speed 980r/min | |||||||||||

| Flow | Head | Efficiency |

Shaft power |

Motor power |

Npsh | Flow | Head | Efficiency |

Shaft power |

Motor power |

Npsh | ||

| OHF Type | OHC Type |

m3 /h |

m | % | Kw | Kw | m |

m3 /h |

m | % | Kw | Kw | m |

|

OHF100 -500 |

OHC100 -500 |

170 | 78 | 64.7 | 55.8 | 75 | 1.2 | ||||||

|

OHF150 -500 |

OHC150 -500 |

280 | 80 | 73.5 | 83 | 110 | 1.8 | ||||||

|

OHF150 -560 |

OHC150 -560 |

320 | 100 | 68.3 | 127.7 | 160 | 2.3 | ||||||

|

OHF150 -630 |

OHC150 -630 |

400 | 133 | 68 | 213.2 | 250 | 3 | ||||||

|

OHF200 -500 |

OHC200 -500 |

505 | 83 | 78 | 146.4 | 185 | 3.3 | ||||||

|

OHF200 -560 |

OHC200 -560 |

500 | 105 | 75.1 | 190.5 | 220 | 2.8 | ||||||

|

OHF200 -630 |

OHC200 -630 |

600 | 130 | 74 | 287.2 | 355 | 4 | 400 | 57 | 72.7 | 85.5 | 110 | 1.8 |

|

OHF250 -315 |

OHC250 -315 |

550 | 30 | 84.2 | 53.4 | 75 | 3.5 | ||||||

|

OHF250 -500 |

OHC250 -500 |

800 | 83 | 82.6 | 219.1 | 250 | 4.5 | 550 | 36 | 81.6 | 66.1 | 75 | 2.2 |

|

OHF250 -560 |

OHC250 -560 |

850 | 105 | 79.1 | 307.5 | 355 | 4.2 | 550 | 46 | 77.9 | 88.5 | 110 | 1.8 |

|

OHF250 -630 |

OHC250 -630 |

850 | 128 | 78.2 | 379.1 | 450 | 4.8 | 550 | 56 | 76.9 | 109 | 132 | 2 |

|

OHF300 -400 |

OHC300 -400 |

1100 | 47.5 | 85.1 | 167.3 | 185 | 7.5 | ||||||

|

OHF300 -500 |

OHC300 -500 |

1250 | 82.5 | 85.8 | 327.5 | 400 | 6.2 | 850 | 36 | 85 | 98.1 | 110 | 3 |

|

OHF300 -560 |

OHC300 -560 |

1400 | 105 | 86 | 465.8 | 560 | 6.2 | 950 | 46 | 85.1 | 140 | 160 | 2.8 |

|

OHF300 -630 |

OHC300 -630 |

1600 | 130 | 82.8 | 684.5 | 800 | 6.8 | 1000 | 58 | 81.7 | 194 | 220 | 2.7 |

|

OHF400 -500 |

OHC400 -500 |

2150 | 75 | 88 | 499.3 | 560 | 10 | 1500 | 32 | 87.2 | 150 | 185 | 4.8 |

|

OHF400 -560 |

OHC400 -560 |

2100 | 100 | 88 | 650.3 | 800 | 8 | 1350 | 45 | 87.2 | 190 | 220 | 3.5 |

|

OHF400 -630 |

OHC400 -630 |

2300 | 130 | 87.4 | 932.2 | 1120 | 10 | 1500 | 57.5 | 86.6 | 271 | 315 | 4 |

|

OHF400 -720 |

OHC400 -720 |

2800 | 175 | 86.1 | 1551 | 1800 | 10 | 1800 | 77 | 85.2 | 443 | 500 | 4.3 |

|

OHF400 -728 |

OHC400 -728 |

4000 | 165 | 90.7 | 1983 | 2240 | 10 | 2600 | 72 | 90.1 | 566 | 630 | 4.5 |

2. Flush plan: API 11、31、21、52、53 etc.

3. Manual or automatic gas and liquid discharge

4. Automatic control measuring instruments: temperature and vibration measuring for bearing 、temperature measuring, leakage measuring for mechanical seal or pressure detection etc.

5. Forced-lubrication system

6. Thermal insulation and heating system

7. Water cooling system

8. ASME companion flange

9. Material: API610 I-1、S-6、A-8、D-1 etc.